FAQ Technical

Q: FM 105 and FM 105 power supplies. Which can be used with FM 155-MKIIR and FM

223?

A: Only the FM 105 p.s. which is delivered with each FM 155-MKIIR can be used for the FM 155-MKIIR. If other p.s. are connected the unit will be damaged massively.

For the FM 223 a similar looking but different power supply is used, the FM 205 (it cannot be used on the FM 155-MKIIR by accident as it has a different connector).

NEVER EVER try to connect any other type or brand of power supplies. Damage occurred from this is not covered by warranty.

Q: What is the recommended warmup time for FM ACOUSTICS equipment?

A: All of FM ACOUSTICS products use a unique elaborate biasing system that guarantees very fast warm up. Products that need an hour or more warm up time or - worse - need to be left running

continuously are simply unacceptable.

The actual warm up time depends on the type of unit and on the time since the last switch on. If the unit has been running a few days ago the warm up time is 5-15 minutes.

If the FM ACOUSTICS unit has not been run for several weeks, it will sound perfect after about 20-30 minutes of warm up.

If the unit was switched off for several months, it is best to run it for an hour or two.

However, no FM ACOUSTICS will ever sound harsh or be unstable on switch on. They sound right immediately from the beginning and will be optimal after the abovementioned times.

Reactivating electronics that have not been switched on for more than 4 months.

A fact not known sufficiently is that electronics (of whatever brand) that have not been switched on for 4-6 months or longer should ideally be preconditioned with a variac. This way they

can be "run in" at low voltage, starting at about 1/3rd of the mains voltage (40V on a 100-120V mains or 80V on a 220-240V supply). Every 10 minutes the mains voltage can then be increased by

about 10V until nominal mains voltage is achieved.

This is because the electrolytic capacitors (that are used in most electronics) are electro-chemical components and age over time. When not having been used for a long time they much prefer a

gradual rise in voltage. An immediate high voltage can weaken a component that has been "dormant".

So if you have a unit that has not been used for many months or years and uses electrolytic caps (and almost everything electronic does as there is no alternative to electrolytic caps in most

applications...), bring it to a technician that has a variac and ask him to "run in" the unit as described above. You may be compensated for this effort by a considerable increase in life

expectancy and reliability.

The lifetime of electrolytic capacitors depends on many variables, such as temperature, voltage rating and voltage applied, ripple current, regular or irregular use, vibration etc. and of course

on the quality of the electrolytic and capacitor itself. Typical lifetime can be anywhere from three years (commercial parts) to fifteen years or so for high reliability and military spec

parts.

In some FM ACOUSTICS amplifiers that have been in regular professional use for 12-24 hours a day, the electrolytics are still in fine shape after 28 years! These are exceptions, however, and

cannot be expected as the average. The usual lifetime of quality capacitors can generally be compared with the lifetime of a top-quality battery.

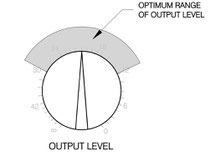

Q: When I listen at reasonable levels the output level control of the FM ACOUSTICS preamp is about at the 9 o'clock position. It gets too loud when I turn it up. What can

I do about this?

A: If this is the case with all types of sources your audio system has too much overall gain.

If your power amplifier has gain controls that do not affect sound quality (unfortunately some level controls do indeed degrade the quality of the audio signal) reduce the level on the power amp

by lowering its volume control.

If there are no gain controls on the power amp or there is an audible change when turning the amplifier's level control, push the -20dB "mute" switch on the FM ACOUSTICS preamplifier.

The newer preamplifiers have the possibility of adjusting gain. Contact your distributor.

If this excessive gain is only apparent with one source, let's say a CD-SACD player/converter, while it is not apparent with other sources, the converter does not adhere to the professional

standards of line level signals and produces excessive output levels.

In other preamplifiers/line stages this can provoke overload of the input stages. All FM ACOUSTICS line inputs have very high overload margin so this is not of concern.

However, the fact remains that there is too much overall gain and "the volume control is in the 'wrong' position".

An optimal gain setting is - if at maximum acceptable volume level - the preamplifier's volume control is close to full level (around the 5 o'clock position) - which will result in a 11 o'clock

to 2 o'clock position at "normal" volume levels. Such a setting will also help protect against an accidental heavy peak impulse that might destroy the speakers.

Note: there is N O T less "reserve" when adjusting the gain as indicated above. The moment an amplifier clips it reached its limit whatever the Volume control position of the preamplifier is

so do not think a Volume control needs to be operated at low levels "to have reserve".

It is NOT a good idea to have excessive overall gain in the system and then run the volume control at low levels (say below the 10 o'clock position).

If this excessive gain is only apparent with one source (say the CD/SACD converter) one solution is to reduce the output level of the converter but this may have a negative influence on sound

quality (digital volume control circuits). If you encounter such a problem the newer FM ACOUSTICS Preamplifier/Line stages also allow special remedies. Contact your distributor with details on

your system and settings.

If you use a phono section that has excessive gain you may be able to reduce the gain setting on the phono preamp (as featured in the FM 223, FM 222 and FM 122 phono linearizers).

As only few manufacturers of "hifi" equipment adhere to standards. Non-standard levels and gain is employed - which is what leads to such issues. In the professional world such problems

hardly occur (only with some semi-pro equipment).

Q: Why does FM ACOUSTICS not use detachable mains cables?

A: The main reason is that the cable is an integral part of these products. By fixing it we can assure the quality of reproduction is optimized and no deterioration can occur.

Also, with a detachable mains cable three additional contacts are added in the mains line. These are unnecessary and wherever possible contacts must be avoided as they are a weak link and it is

always better to have as few contacts as possible.

This is also the fact with the widely used "Euro" plugs - which may be acceptable for low power - are not suitable at all for high currents. While their theoretical ratings suggest that they can

handle high power, practical experience shows that the contacts of these plugs are not optimal and often there is quite a bit of "play" between the plug and the socket. Due to this, the actual

area making contact is rather small, clearly too small for high current demands. The higher the power demand the more important this issue is. As the contact is not perfect, micro-arcing makes

these contacts loose their initial more or less reasonable surface. Thereby additional resistance is added into the mains line, certainly not what is wanted in precision audio...

No "vodoo" cable will help as they all are limited by these inferior contacts.

The lower the impedance, the better - the fewer contacts in a product the better it will perform and the better will be reliability.

Q: In your cables, why do you not use silver as conducting material?

A: Just because silver is a bit more costly a raw material does not mean that it gives better performance.

The usual reason quoted for using silver is that silver's conductivity is better. Correct, but the difference to copper is a mere 2%. Therefore, by adding 2% more copper in the cables the

improved conductivity attributable to silver is effectively negated. By increasing the pure copper content up to the optimum, performance will surpass that of the best silver cable (incidentally,

there is no speaker cable with a satisfactory square section made out of pure silver). Other characteristics (such as e.g. shore hardness, oxidation etc.) make silver definitely less desirable

than copper.

However, one must be aware that considerable quality differences exist between the different copper cables. It is very important what kind of copper is used, how it is purified, how it is drawn,

how the strands are prepared, etc. These differences can be audible.

Q: You have a large range of interconnect cables. Which type of interconnect cables should be used between the various units?

A: For detailed explanations and recommendations see under PRODUCTS - AUDIOPHILE: Interconnect-, Phono- and Speaker cables.

Furthermore, you will find drawings and information in the download section under "Technical Bulletin 31" with precise information for many applications.

Q: What preventive maintenance is recommended?

A:In the large power amplifiers its is important to clean the fan filters regularly, a least every 3 months. This can easily be accomplished with a vacuum cleaner. When very dirty, fan filters

can be washed and let dry before re-installation. After having been washed a few times, the filter must be replaced with a new one.

In case of the switches on FM ACOUSTICS line level equipment it is recommended to activate them 10-20 times every 3-6 months. That helps the contacts to perform the cleaning action and preserves

conduction. The same applies for all input and output connectors of any type: just unplug and re-plug them a few times to assure optimal contact. This is especially needed in polluted areas and

humid climates.